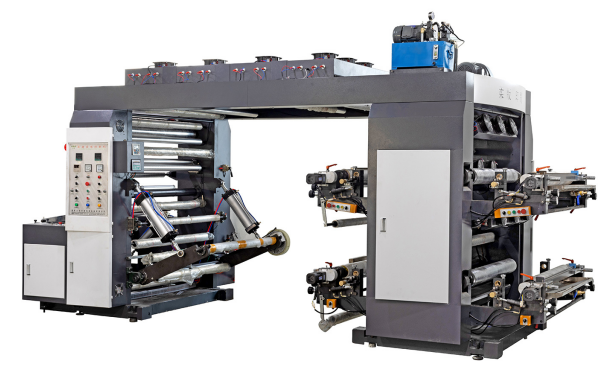

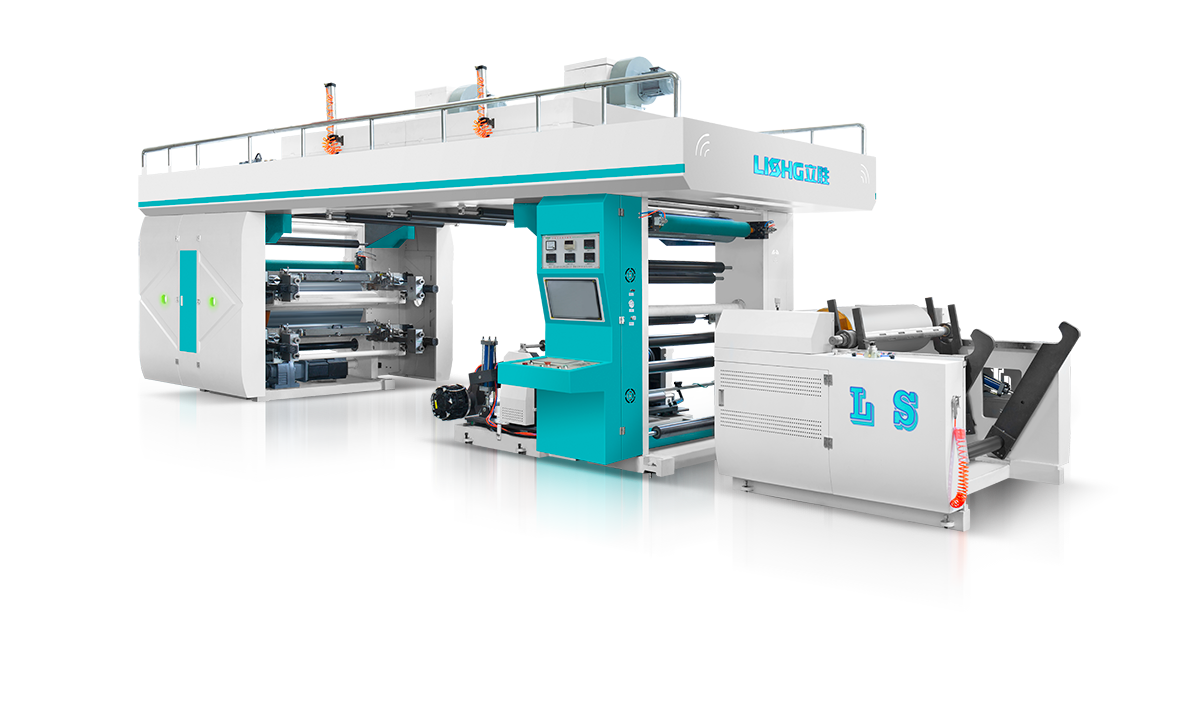

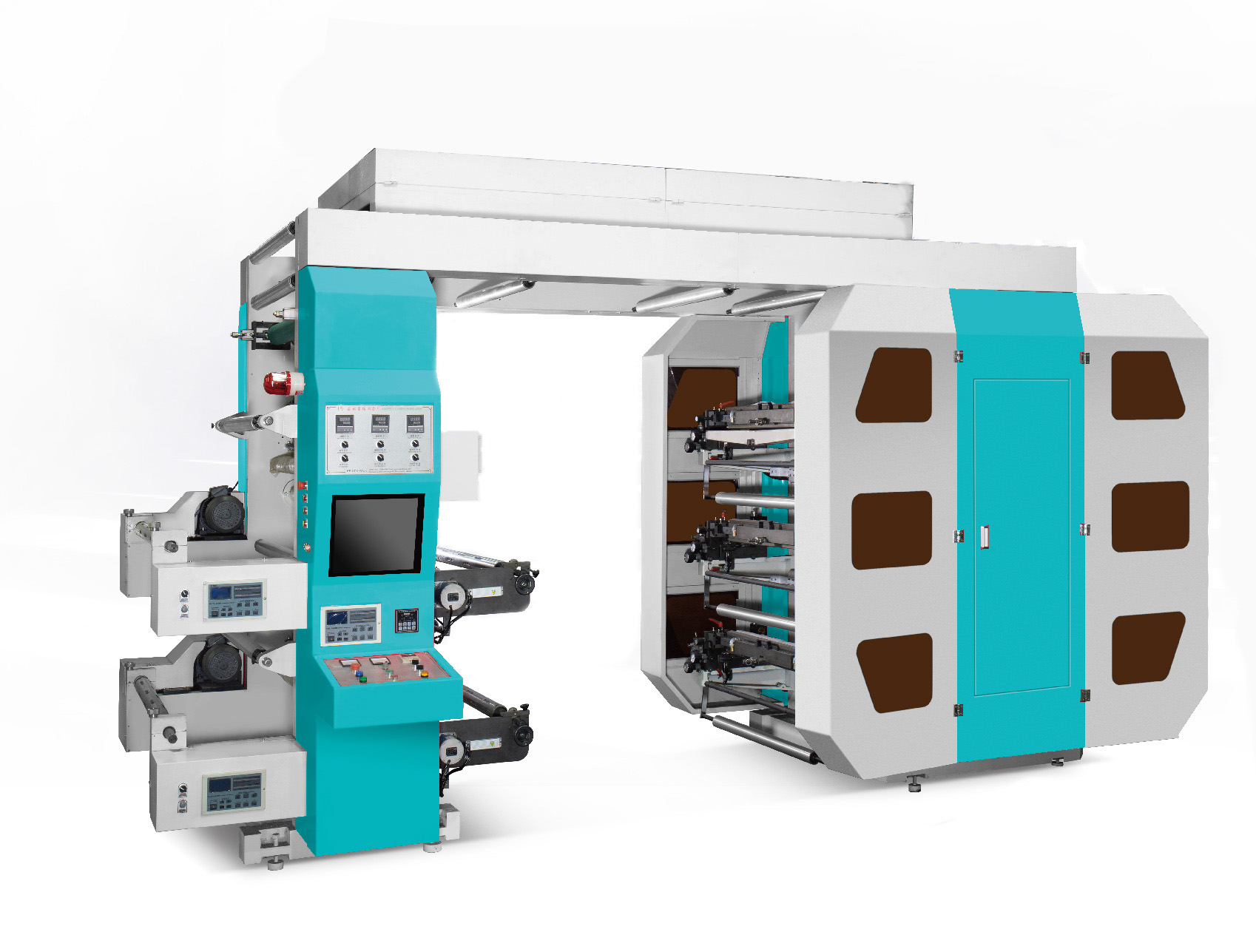

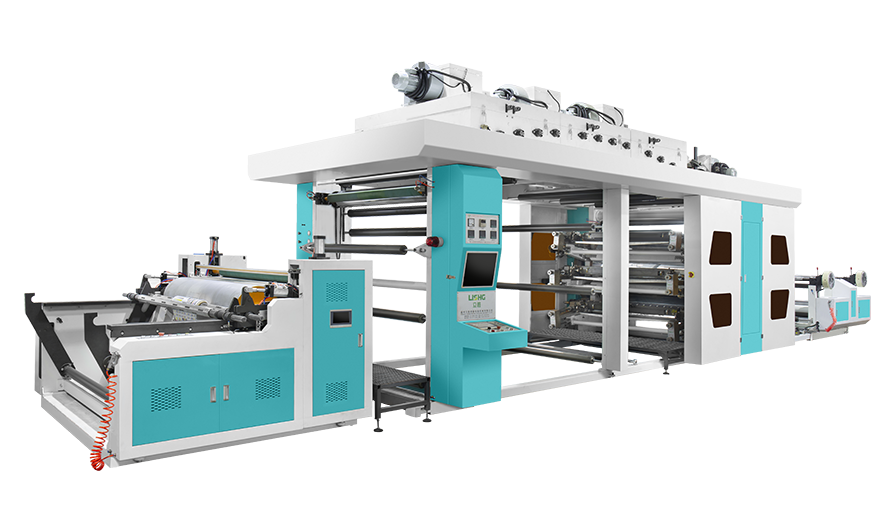

The CI Flexographic Printing Machine, with its continuous, stable, and eco-friendly attributes, is spearheading a global revolution in printing technology. It operates through a continuous roll-to-roll process, perfectly catering to high-quality printing needs on various flexible packaging materials such as plastic films, paper, and aluminum foil. A standout feature of the CI Flexographic Printing Machine is its exceptional production efficiency. Its continuous rolling mechanism significantly boosts printing speed and capacity, ensuring consistent and stable print quality while effectively reducing costs and enhancing economic benefits. Furthermore, it boasts green credentials – a significant advantage over traditional methods. Using water-based or UV-curable inks, CI Flexographic Printing reduces VOC emissions significantly, aligning with international environmental standards and supporting sustainable business practices. The light pressure applied during flexographic printing also minimizes substrate damage, promoting resource conservation and environmental protection. Additionally, CI Flexographic Printing Machines offer high printing precision and excellent color reproduction capabilities, whether dealing with fine lines, minute dots, or large solid areas, delivering vivid and impactful visuals that enhance product competitiveness in the market. In summary, the CI Flexographic Printing Machine, with its "four highs" of high speed, high efficiency, high eco-friendliness, and high quality, has become the preferred choice for numerous packaging printing enterprises both domestically and internationally. We firmly believe that in the future of printing industry, the CI Flexographic Printing Machine will play a pivotal role in ushering in a new era of green, intelligent, and efficient printing. As a professional provider of CI Flexographic Printing Machines, we are dedicated to offering cutting-edge products and comprehensive technical support. We eagerly anticipate partnering with you to forge a brilliant future in the realm of printing!

Read more

In recent years, flexographic printing has developed rapidly in the domestic market with its unique advantages in packaging printing, especially in the fields of labels, flexible packaging, corrugated cartons, aseptic liquid packaging, paper cups and bags, napkins, etc. Flexographic printing has been widely used. The reasons for this are the following three major attributes:

Read more

The current flexo printing market quality characteristics are: large pattern, large color block, text, lines, medium thick dot (printing plate plus network cable number in 133 lines/inch below), the best color gamut for the middle tone (dot area in more than 2% ~ 3%, 70% below the area of the circular network image level performance is the strongest).

Read more

(1) Drawing paper wool. The main reason is that ink viscosity is too large or poor paper strength. The elimination method is to add the appropriate amount of ink removal agent, reduce ink viscosity, the use of high surface strength paper, reduce the speed of the press.

Read more

Traditional printing industry now lags far behind the development of the Internet industry, saving printing costs has become a key issue. The drum of the printing press plays a vital role in the printing quality. The following for you to explain the maintenance of the printing press drum.

Read more

Maintenance of printing press Printing press is one of the most efficient equipment in printing plant. To ensure the normal operation of the printing press, daily maintenance and maintenance is essential and very necessary. Below from the following aspects to talk about the daily maintenance and maintenance of the machine.

Read more

1. Be sure to reserve bleeding lines Text on the page must be spaced from the cropped edge. 3mm, so as not to be cut when cutting. 2. Twist. With software such as CoreIDRAW, text must be curvy or framed, otherwise the font will be missing. After the text is curved, please pay attention to whether there is skipping or overlapping between the words or lines. Try not to use the system word, if used will cause the stroke interleaved white nodes. If there are white nodes at the interlacing of strokes, it can be handled with the instruction of shattering.

Read more

In the use of offset printing press to print PVC self-adhesive materials, ink adhesion is small, PVC self-adhesive material on the back sticky dirty has been a problem plaguing printing manufacturers.

Read more

The intermittent semi-rotary trademark machine using the round flattening process is another upgrade in the history of trademark machine equipment. Its printing quality is better than that of the baroclinic trademark machine. But in a short period of time developed satellite - type high - speed all - wheeled trademark machine to suppress its halo. Rotary trademark machine adopts circular press processing technology, its process principle is basically the same as offset printing, so that its printing quality is comparable to offset printing. And the trademark machine uses roll material, printing and making self-adhesive trademarks and labels can use automatic labeling machine, automatic labeling for goods, so that the trademark machine market has been rapid development.

Read more

The press is the key to flexographic printing. All printing data comes from the press, and in every printing job preparation measure, job quality and careful maintenance of equipment contribute to a successful printing. Successful printing depends on the skill used, the skill of the printer, and the mechanical properties of the press itself. Because all printing job preparation steps are interconnected and interact with each other, it is important not to simplify printing job preparation.

Read more

Cascade flexographic press, sometimes called stack flexographic press. Separate printing units are stacked up and down, arranged at one or both ends of the main wall panel of the printer, or mounted on a rack with various color printing units.

Read more

struggling-to-become-the-target-of-the-printing-industry

Read more