Main parameter:

|

Model |

YT |

|

Material feeding width |

600mm/ 800mm /1000mm |

|

Max Printing Width |

560mm /760mm /960mm |

|

Material |

Film ,paper ,nonwoven |

|

Thickness of plate |

1.7mm 2.28mm 3.94mm Can be customized |

|

Printing length |

300-1000mm |

|

printing speed |

50m/min |

|

Register precision |

±0.5mm |

Characteristics:

1.Easy operation, flexible starting, accurate color register.

2.The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off.

3.manual printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4.The printing ink is spread by the anilox cylinder with even ink color.

5.Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops.

6.360°continuous and adjustable longitudinal register device.

7.The frequency control of motor speed adapts to different printing speeds.

8.There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

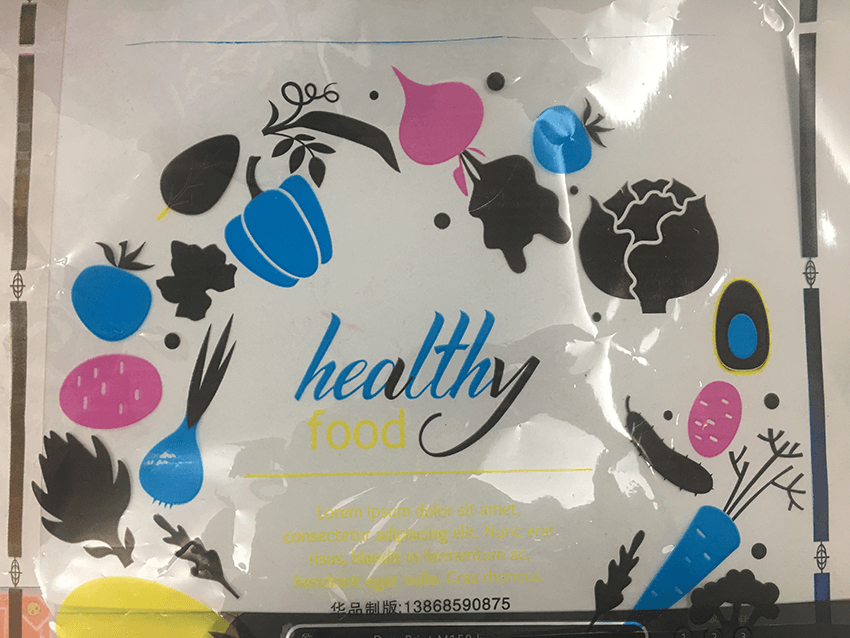

Printing Sample:

|

|

|

Pre-Sales One-stop Service

* Inquiry and consulting support

* Latest industry trends

* More fit printing solution

* Sample testing support

* View our Factory

* Suggest layout support

|

After-Sales Service

* One year warranty

* Machine test video before delivery

* English Manual, Electric Diagram

* Training how to install the machine, training how to use the machine

* Engineers available to service machinery overseas

|

Our company pictures let you know about my company

|

|

|

|

|

|

|

|

|

- Flexo Printing Machine Counselor

- Contact Name: Nancy Zhang

- E-mail: sales11@lishengmachine.com

- Mobile Phone: +86 13588976785

- WeChat: +86 13588976785

- WhatsApp: 8613588976785