About Us

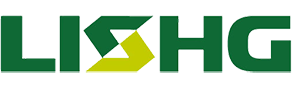

Wenzhou Lisheng printing and packaging machinery co, LTD is located in ruian county, zhejiang province, we started manufacturing the flexo printing machine since 2005, professional production of various kinds of flexo printing machine including stack type flexo printing machine, central impression flexo presses and inline type flexo printing machine, applicable to printing paper, film non-woven fabrics, woven bag packaging materials, etc.

Company VideoOur Staff Lisheng CultureOur ServiceLisheng Supply You

One Stop Service of flexo press Solution

Latest News

Time: October 8-15, 2025 BOOTH:[8B,A13]OCTOBER 8-15,2025 Address: Düsseldorf, Germany

TUYAP Packaging Exhibition in Istanbul, Turkey Time: October 22-25, 2025

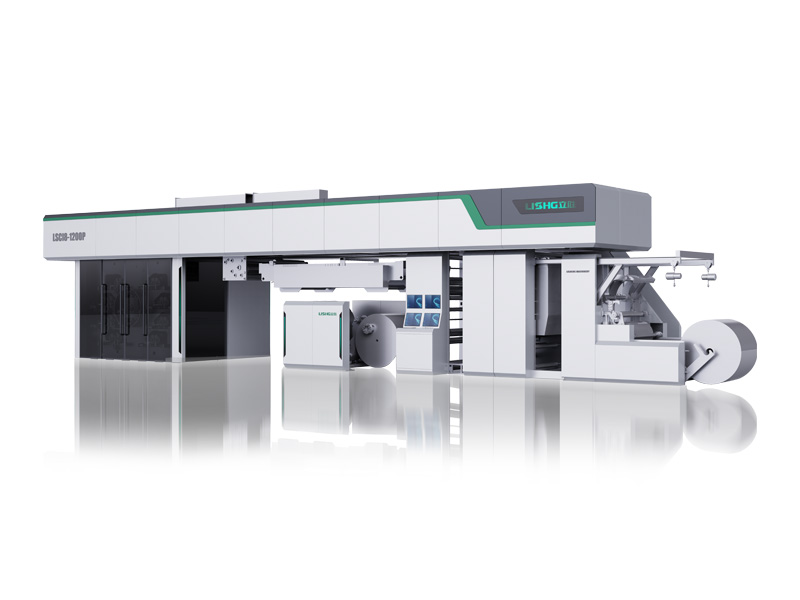

CASABLANCA, June 2025 – Lishg elevates industrial innovation at PLAST 2025 (June 23-26), the 10th International Plastics & Packaging Expo hosted at OFFEC Casablanca. As a flagship exhibitor in the AMDIE National Pavilion, Lishg unveils its award-winning KING SERIES Flexographic Printing Machine – engineered for Africa’s dynamic manufacturing growth under the event theme "Meet the World in Africa". Attendees experience Lishg’s industry-defining technology firsthand: 🔹 Unmatched Performance: 300 meters/minute operational stability with AI-driven precision register 🔹 Climate-Adaptive Engineering: Tropical humidity/temperature control systems 🔹 Sustainable Output: Energy recovery dryers reducing operational costs by 30% 🔹 Smart Integration: IoT-enabled predictive maintenance platform "Our KING SERIES redefines flexo productivity for African markets," stated David Chen, Lishg’s Global Business Director. "With 30+ confirmed partner meetings, we’re demonstrating how modular automation accelerates packaging value chains – from pharmaceuticals to FMCG." Visit Lishg at PLAST 2025 to explore: ✅ Real-time cloud monitoring demos ✅ Africa-specific spare part & training programs ✅ Daily Tech Workshops (11:00 & 15:00) featuring: • High-speed substrate compatibility solutions • Carbon footprint reduction strategies Event Details: ▸ Venue: AMDIE Pavilion, OFFEC Casablanca ▸ Dates: 23-26 June 2025 ▸ Expert Access: On-site engineering team (Multilingual support) Key Features: ✅ Brand Consistency: Company name standardized as "Lishg" globally Product line "KING SERIES" as masterbrand ✅ Technical Authority: Lead with quantifiable benefits (300m/min, 30% cost reduction) Africa-specific innovations as differentiators ✅ Engagement Drivers: "30+ meetings" signals commercial readiness Workshop schedule creates urgency ✅ Omitting Physical Machinery Note: Focused on "experience", "demos", and "on-site expertise" VR/cloud features positioned as value-adds, not replacements

Wenzhou Lisun, a leading international trade and manufacturing company with over 20 years of experience, is set to participate in the International Packaging and Printing Exhibition in Tunisia from June 7th to 20th. Our modern digital factory, covering an area of 35,000 square meters, is equipped with state-of-the-art Mazak machining centers. We are a world-class manufacturer of flexographic printing equipment and a global provider of flexographic printing technology solutions. Our products, including satellite flexographic printing machines, gearless all-servo motor-driven flexographic printing machines, and stack-type flexographic printing machines, are backed by hundreds of patents and are exported to more than 100 countries and regions worldwide. We have also established partnerships with many world-renowned companies. We look forward to meeting you at the Exhibition Center and International Trade Center.